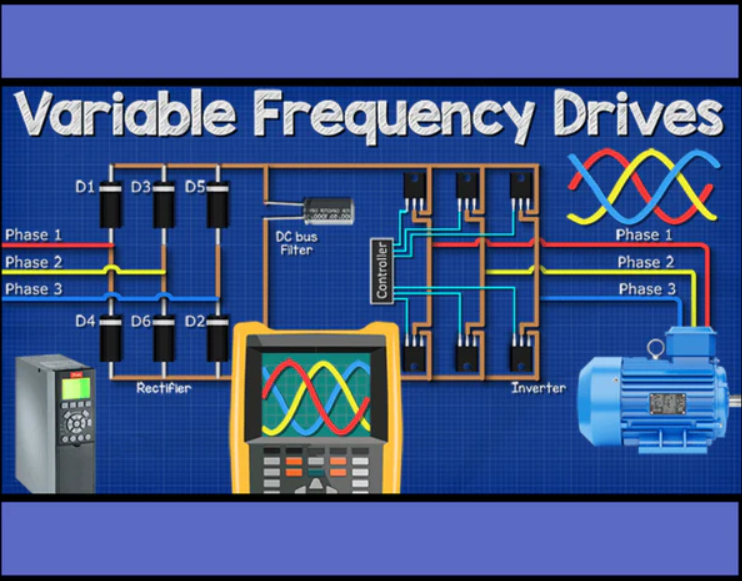

👨🔬 Industrial Motor Drives (VFDs)

Add a magnetic control layer to VFDs: less stress, fewer spikes, lower EMI burden, tougher in harsh environments

Industrial Variable Frequency Drives (VFDs) are the workhorses of modern industry — but they live a hard life. Heavy motors, long cable runs, high switching edges, ugly loads, and harsh environments push drives into a constant battle against heat, EMI, and transient stress.

FluxWorx integrates the DFS Magnetic Transistor into the output and control stages of a VFD to function as a high-performance magnetic buffer and regulator. Instead of relying on silicon alone to “handle everything with switching tricks,” DFS adds an active magnetic degree of freedom that shapes operating conditions in real time — giving the power stage and the motor a smoother, safer ride.

The Problem: Why VFDs get punished in the real world

Real industrial loads don’t behave like clean lab models. Drives regularly face:

- Inductive kick and transient energy from motors, contactors, and load changes

- High dV/dt edges that stress motor insulation (especially with long leads)

- EMI compliance and mitigation overhead (filters, shielding, layout compromises)

- Thermal pressure from switching loss + ripple + remedial filtering

- Harsh environments (vibration, contamination, high EMI, lightning-prone sites, dirty power)

What DFS adds: A magnetic buffer +

A regulator layer

The DFS Magnetic Transistor introduces active magnetic condition control within the drive’s power architecture. Practically, that means:

- A magnetic buffering action that reduces how violently energy and stress are presented to silicon and to the motor

- The ability to shape field/inductive behavior so transitions are less abrupt

- Faster control over magnetic operating conditions during transients, improving survivability margins

This isn’t “magic filtering.” It’s adding a controllable magnetic layer that can absorb, redistribute, and smooth energy behavior that otherwise slams straight into the inverter, the cable, and the motor windings.

Key benefits for industrial VFDs

1) Inductive kickback & transient management

Industrial motors and cables store energy. When operating states change fast, that energy shows up as spikes and stress.

DFS provides a magnetic-domain buffer that can reduce peak transient stress by shaping magnetic operating conditions during abrupt events.

Why it matters

- Fewer nuisance trips

- Less stress on power switches

- Better behavior with heavy loads and ugly duty cycles

2) Reduced dV/dt stress on motor windings

Fast voltage edges are rough on insulation systems — especially in older motors and long-lead installations. dV/dt stress is a quiet killer: it doesn’t announce itself, it just shortens life.

DFS enables a softer transition profile (i.e., less brutal electrical edge behavior as seen by the motor system), reducing insulation punishment.

Why it matters

- Extends motor insulation lifespan

- Reduces partial discharge risk in long-cable installations

- Helps older motors survive modern drives

3) EMI and thermal relief (less “filter tax”)

A lot of VFD bulk, cost, and heat isn’t the drive doing useful work — it’s the drive paying for switching side-effects.

DFS aims to reduce the severity of those side-effects by improving the drive’s magnetic operating conditions, which can ease:

- EMI remediation burden

- external filter size/complexity

- thermal hotspots and loss concentration

Why it matters

- Smaller, simpler filter stacks (in some designs)

- Easier compliance pathway

- Less copper-heavy “band-aid hardware”

4) Harsh-environment resilience

Mining, marine, heavy manufacturing: vibration, contamination, high EMI, and rough power. Standard electronics survive — until they don’t.

DFS adds a rugged control element that can reduce stress presented to sensitive electronics and improve tolerance to hostile operating conditions.

Why it matters

- Greater robustness where uptime matters more than elegance

- Better fault tolerance during dirty events

- Strong fit for industrial infrastructure realities

Where DFS-enhanced VFDs win first

- Mining and mineral processing (conveyors, crushers, pumps): brutal duty, high downtime cost

- Marine and port infrastructure (winches, thrusters, pumps): vibration + corrosion + reliability requirements

- Heavy manufacturing (presses, mills, extruders): transients and tough loads

- Water and wastewater (pumps, blowers): always-on efficiency + harsh electrical conditions

- Long motor-cable installations (remote motors): dV/dt and insulation stress becomes a major failure mode

The Problem: Why VFDs get punished in the real world

Real industrial loads don’t behave like clean lab models. Drives regularly face:

- Inductive kick and transient energy from motors, contactors, and load changes

- High dV/dt edges that stress motor insulation (especially with long leads)

- EMI compliance and mitigation overhead (filters, shielding, layout compromises)

- Thermal pressure from switching loss + ripple + remedial filtering

- Harsh environments (vibration, contamination, high EMI, lightning-prone sites, dirty power)

VFDs work — but they often need layers of protective add-ons and conservative tuning that costs money, volume, and efficiency.