👨🔧 Switch Reluctance Motors (SRMs)

The rugged, rare-earth-free motor the world wants — once we fix the noise, ripple, and control pain

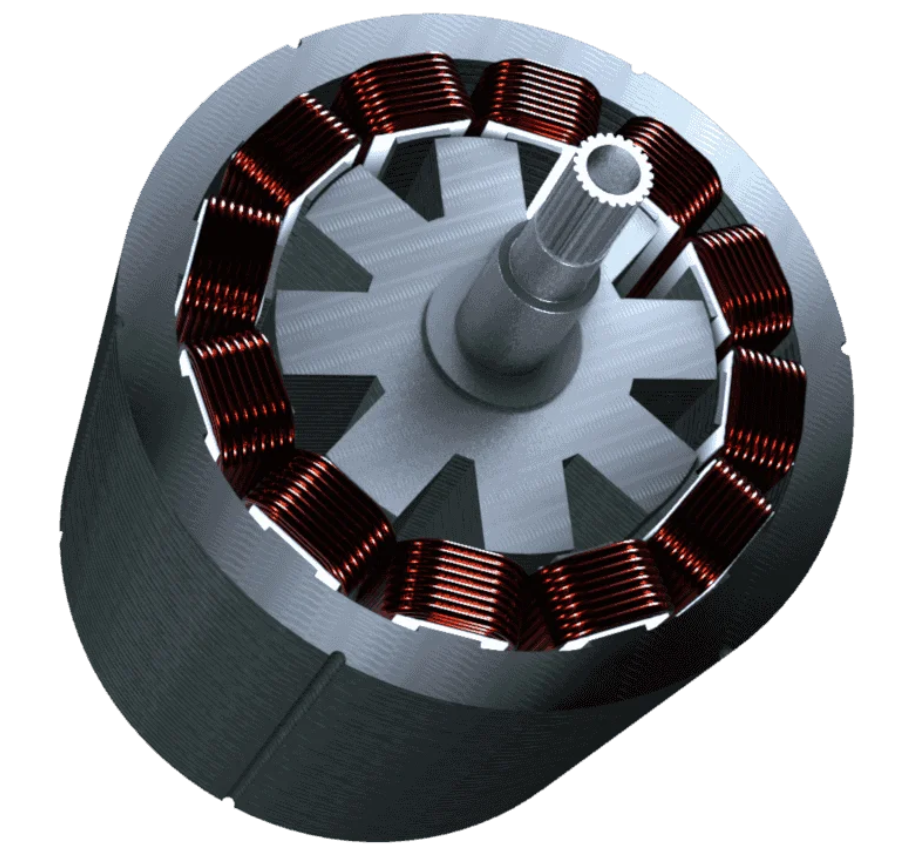

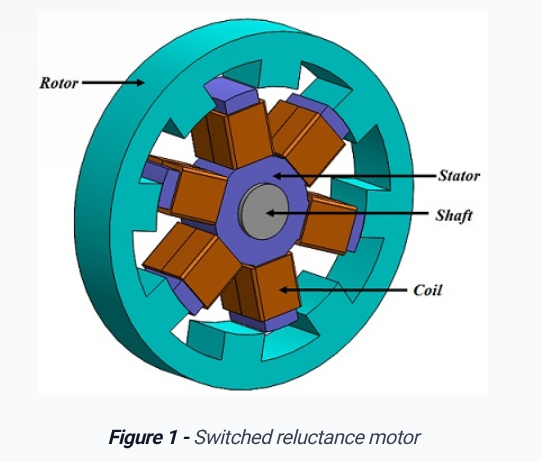

SRMs have been the “obvious” motor for decades: simple rotor (no magnets, no windings), high temperature tolerance, rugged construction, and a supply chain that doesn’t depend on rare-earth materials. If you were designing a motor for a resource-constrained, geopolitically messy, electrified world… SRM is the clean choice.

And yet, SRMs aren’t the default in EV traction and high-end motion control — for one reason: they’re brilliant on paper, but historically painful in the real world. Torque ripple, acoustic noise, vibration, current ripple, and control complexity have kept SRMs in the “great niche motor” box instead of the “motor for everything” box.

That’s exactly where FluxWorx DFS (Differential Flux Steering) comes in. The DFS Magnetic Transistor is designed to shape the magnetic drive conditions feeding the motor — so the SRM keeps its simplicity and cost advantages, while the classic SRM shortcomings get pushed down hard.

The Problem: Why SRMs haven’t dominated (yet)

Classic SRM operation produces sharp changes in magnetic conditions across the electrical cycle. That’s great for torque production — but it also tends to create the stuff customers hate:

- Torque ripple → vibration, harshness, reduced perceived quality

- Acoustic noise → the “angry vacuum cleaner” problem

- Current ripple + EMI burden → tougher filtering, layout, shielding and compliance work

- Control sensitivity → position sensing, calibration, edge-case tuning

- High-speed compromises → drivability and efficiency tradeoffs

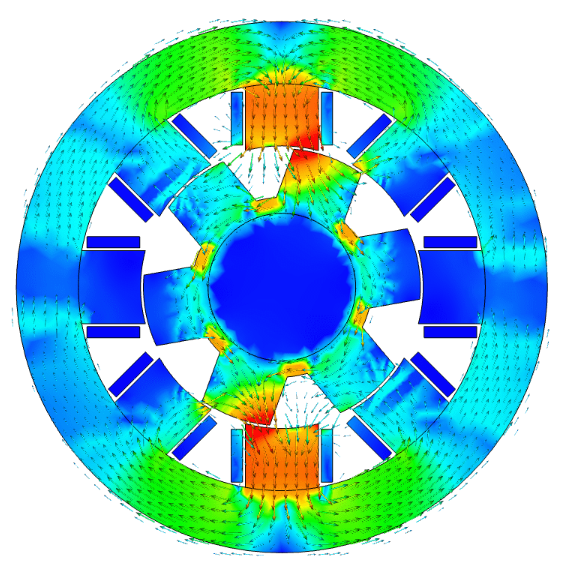

What DFS changes in an SRM

DFS adds an actively controlled magnetic degree of freedom between the drive electronics and the motor’s magnetic system. Instead of relying only on “hard switching + current shaping” to force the SRM to behave, DFS enables magnetic condition shaping — actively biasing operating conditions so torque production is smoother, quieter, and easier to control.

Think of it like this: traditional SRM control tries to “fix” mechanical feel using only electronics. DFS gives you a second tool: magnetic waveform/field shaping. That’s how you keep SRM’s brutal simplicity while making it drive like a premium motor.

Practical outcomes we target

- Lower torque ripple (smoother torque delivery through the cycle)

- Reduced acoustic noise (less excitation of mechanical resonances)

- Less current “violence” (reduced ripple burden and easier EMI life)

- Better high-speed behavior (improved controllability as operating points shift)

- More tolerant control (less edge-case tuning and fewer “gotchas”)

Why this matters: SRM economics are unbeatable

The SRM value proposition is simple and very 2026:

Think of it like this: traditional SRM control tries to “fix” mechanical feel using only electronics. DFS gives you a second tool: magnetic waveform/field shaping. That’s how you keep SRM’s brutal simplicity while making it drive like a premium motor.

Practical outcomes we target

- No rare-earth magnets → supply resilience + cost stability

- Simple rotor → robust, high-temperature, high-speed capable

- Manufacturing friendliness → steel + copper supply chains you can scale

- Ruggedness → harsh environments, overload tolerance, long service life

If DFS removes the “SRM penalty stack” (noise + ripple + tuning pain), SRM stops being a niche choice and becomes the default choice for a huge slice of motion and traction.

Where DFS-enhanced SRM wins first

- Industrial drives (pumps, fans, compressors): rugged + efficient + lower NVH

- Off-road / work vehicles: thermal tolerance and durability matter more than glamour

- Fleet EVs (delivery, buses): cost, reliability, and serviceability dominate

- Harsh environment motion (mining, marine, defense): where magnets and fragility hurt

- Robotics / actuators: smoother force curves without over complicated systems

How we prove it: an OEM-friendly evaluation

We validate with data, not vibes. We propose an NDA-backed 6–8 week A/B evaluation against a reference SRM drive:

- Torque ripple comparison (time-domain + frequency-domain metrics)

- NVH pack (acoustic signature + vibration indicators under matched load points)

- Efficiency map (key speed/load points, plus thermal rise comparison)

- Drive stress indicators (current ripple, switching stress proxies, hotspot behavior)

- Integration notes (control interface, limits, fail-safe behavior)

No hype. Just plots, thermals, and torque traces. The only kind of romance engineers respect.

Closing

If SRM is the motor for our age, DFS is the missing piece that makes it feel like one.

© FluxWorx — www.fluxworx.org